Clock Chime Hammer Positioning

Why Does Chime Hammer Positioning Need to Occur

Mechanical clock chime hammer positioning is easy to do. It only involves bending the hammer head wires. Upon the initial installation, this was done by the clock maker as well.

When replacing a clock movement you need to bend the chime hammers to the chime rods. This is why the hammer heads are on bendable wires.

They are meant to be bent into the perfect position. It is not uncommon to bend them an inch this way or that way. The clock movement will not have the hammers in the perfect spot to make the correct sound when hitting the rods. This is why chime hammer positioning is so important.

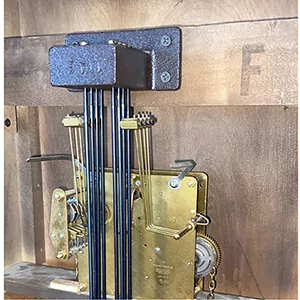

Click on the picture to shop Chime Hammers on Clockworks.com

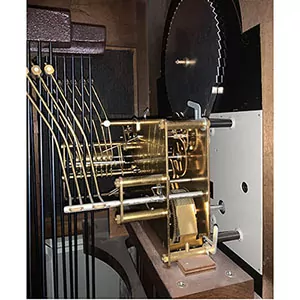

Click on the picture to shop Chime Rods on Clockworks.com

Clock Chime Hammer Positioning

A mechanical clock movement has hammers that need to be bent into their final position. The correct clock-chime hammer position needs the tops of the hammer heads to be about 1/4 inch down from the chime block.

The hammers need to be 1/8 inch away from the rod. This would be when it is at rest. In other words, bend the hammer wires so the head is 1/8 away from the chime rod. This spacing between the head and the rod is so it will not thud or double strike.

Tuning the Mechanical Clock Chime

Repeat this process for each wire, one hammer at a time, down the line. Continue in this manner until you can lift and drop the hammer to create a crisp sound. If each hammer head is done this way the clock will have a nice song in the end.

Often a customer will say the sound is not correct. This is due to improper hammer positioning. When performing the above directions correctly the sound is beautiful.

Positioning the 340 / 341 Series

The 340 and 341 Hermle clock movement series went through a change in the hammer wires. The hammer heads were on wires, but now they are made on flat bars. The positioning is still the same, however it is a little more difficult to bend them.

The hammer head is on the skinny end of the bar. The bar gets wider as it goes back toward the roll pin.

With needle nose pliers, bend this bar where it goes from skinny to wide. The overall assembly will be slightly higher from the chime block. That is, if you are swapping out the movement with the older style wire hammer head rod.

It is an option to raise the entire chimeblock with a shim to help with this. It is not an absolute requirement. Bending the hammer arms are usually sufficient.

A clean crisp chime sound

Adjust the hammer wires

Should be about 1/8 away at rest

Sometimes they are bent to the extreme

*The content of this website is copyright by Clockworks Inc.

Updated on: 06/08/2025

Thank you!