Making a Grandfather Clock Seat Board

Making a Grandfather-Clock Seat-Board

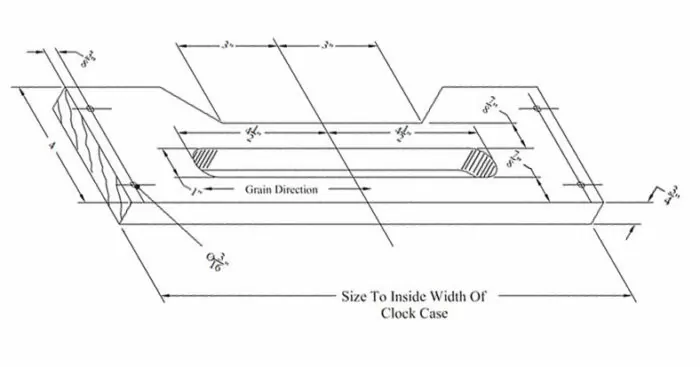

Making a Grandfather-Clock Seat-Board, which is the mount that the weight driven movement sits upon, is fairly easy.

Of course, the movement sits on this with cables or chains. Subsequently, they hang directly down between the boards.

Typical approximate dimensions

Additionally, many of the modern clocks have a seatboard that is 16 inches wide and is 2 and a half inches deep. However this varies depending on the clock case dimensions.

In the center of the mounting board is a hole that is 1 inch wide. It goes across the center of the 2 and a half inch deep seat board.

Putting it together

The hole is wide enough for the movement to sit on the board with its chains hanging down in the center. Then the seat board screws and washers can go up into the movement’s arbors on the bottom.

These are the screws with the rectangle washers. Of course, an easier method would be to mount two, three quarter or 1 inch square boards running parallel, which are 1 inch apart, across the inside of the clock case. This is really all a mounting board needs to consist of.

The only thing that has to happen is the movement is in the air with the chains dangling down in between these boards. The boards just can’t be so wide that the pendulum rubs it on the back of the movement.

With the movement mounting in the air, all that needs to be done is have the chime block mounted.

This goes on the back of the clock case. This enables the hammers to engage with the rods for the chime sound. Next hang the weights and pendulum. The final step is to lock the dial into the movement from the front.

plywood seat board

plywood seat board

any ways to make a seat board

any ways to make a seat board

simple test stand

simple test stand

lock case seat board

lock case seat board

[post-content id=100711 shortcodes="true"]

Updated on: 27/12/2024

Thank you!